ARC STUDS

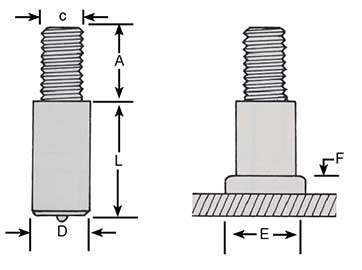

SHOULDER SB

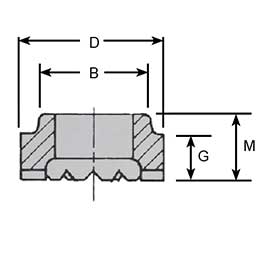

| D | MIN L | C | A | E | F | D | B | G | M |

| 1/4 | 5/26 | 8-32 | 13/32 | 23/64 | 7/64 | .455 | .380 | .234 | .390 |

| 5/16 | 11/32 | 10-24 | 15/32 | 7/16 | 7/64 | .578 | .445 | .234 | .390 |

| 3/8 | 3/8 | 1/4-20 | 5/8 | 1/2 | 1/8 | .640 | .505 | .234 | .390 |

| 7/16 | 7/16 | 5/16-18 | 25/32 | 19/32 | 9/64 | .703 | .585 | .234 | .422 |

| 1/2 | 1/2 | 3/8-16 | 15/16 | 11/16 | 5/32 | .795 | .650 | .250 | .438 |

| 5/8 | 5/8 | 1/2-13 | 1-1/4 | 7/8 | 3/16 | 1.030 | .785 | .328 | .516 |

| 3/4 | 5/8 | 5/8-11 | 1-9/16 | 1-1/16 | 1/4 | 1.215 | 1.030 | .469 | .656 |

| 7/8 | 3/4 | 3/4-10 | 1-7/8 | 1-1/8 | 5/16 | 1.408 | 1.210 | .545 | .732 |

SHOULDER STUDS: Threaded studs with a weld base diameter greater than the thread diameter.

DIAMETER: Available in diameters from 1/4" through 3/4", in thread diameters to maximum (C).

LENGTH: Available in required lengths above the recommended standard minimums (L). The minimum overall length is determined by a combination of L and the required A. The length is before weld. Stud diameters 1/2" and smaller will be approximately 1/8" shorter after welding. Diameters of 5/8" and larger will be approximately 3/16" shorter after welding.

MILD STEEL: Low carbon steel.

- Mechanical Properties (as cold drawn):

- Tensile: 55,000 psi min.

- Reduction in Area: 50% min.

STAINLESS STEEL: Type 304 is the most commonly used. Other grades of stainless steel (except Type 303) are available when required.

THREAD: Standard thread is UNC2A.

FERRULES: All orders for studs include required ferrules.

PLATING: Plated studs are available in cadmium, zinc, and nickel, ASTM specifications A165 Type TS, A164 Type RS, and B-456. The welding end of the stud is not plated to prevent weld contamination. Information on other plating materials are available upon request.

ANNEALING: Stud ductility can be increased by annealing to 75 Rockwell B for low carbon steel and 90 Rockwell B for stainless steel.

FLUX: Studs 1/4" and over are solid fluxed.