ARC STUDS

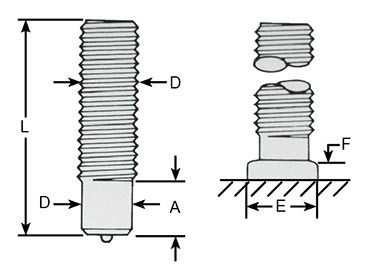

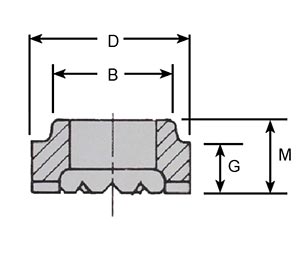

PARTIAL THREAD ARCPT

| D | MIN L | C | A | E | F | D | B | G | M |

|---|---|---|---|---|---|---|---|---|---|

| 1/4-20 | 5/8 | .215 | 3/8 | 5/16 | 3/32 | .455 | .385 | .125 | .250 |

| 5/16-18 | 43/64 | .275 | 3/8 | 13/32 | 7/64 | .535 | .445 | .125 | .250 |

| 3/8-16 | /32 | .330 | 3/8 | 15/32 | 7/64 | .590 | .505 | .139 | .264 |

| 7/16-14 | 15/16 | .387 | 7/16 | 17/32 | 1/8 | .675 | .585 | .173 | .329 |

| 1/2-13 | 1-1/32 | .448 | 1/2 | 19/32 | 5/32 | .740 | .650 | .206 | .362 |

| 5/8-11 | 1-13/64 | .562 | 5/8 | 3/4 | 3/16 | .910 | .785 | .277 | .433 |

| 3/4-10 | 1-7/16 | .680 | 51/64 | 59/64 | 1/4 | 1.150 | 1.030 | .339 | .526 |

| 7/8-9 | 1-39/64 | .798 | 55/64 | 1-3/64 | 5/16 | 1.330 | 1.210 | .406 | .593 |

| 1-8 | 1-51/64 | .915 | 59/64 | 1-3/16 | 11/32 | 1.526 | 1.406 | .474 | .661 |

PARTIAL THREAD: The studs have a pitch diameter weld base.

DIAMETER: Available in diameters from 1/4” through 1”.

LENGTH: Available in required lengths above the recommended standard minimums (L). Length is before weld. Stud diameters 1/2” and smaller will be approximately 1/8” shorter after welding. Diameters of 5/8” and larger will be approximately 3/16” shorter after welding.

MILD STEEL: Low carbon steel.

- Mechanical Properties (as cold drawn):

- Tensile: 55,000 psi min.

- Reduction in Area: 50% min.

STAINLESS STEEL: Type 304 is the most commonly used. Other grades of stainless steel (except Type 303) are available when required.

THREAD: Standard thread is UNC2A. Maximum standard thread length is 3-7/8”.

FERRULES: All orders for studs include required ferrules.

PLATING: Plated studs are available in cadmium, zinc, and nickel, ASTM specifications A165 Type TS, A164 Type RS, and B-456. The welding end of the stud is not plated to prevent weld contamination. Information on other plating materials are available upon request.

ANNEALING: Stud ductility can be increased by annealing to 75 Rockwell B for low carbon steel and 90 Rockwell B for stainless steel.

FLUX: Studs 1/4” and over are solid fluxed.